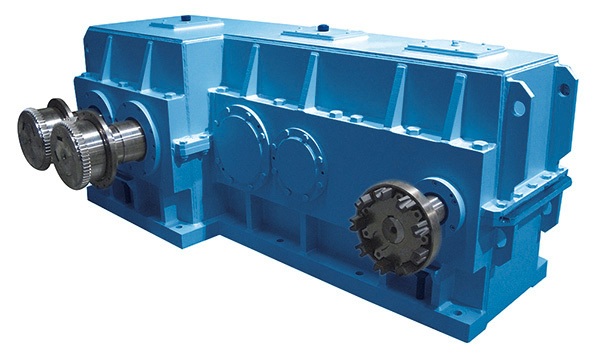

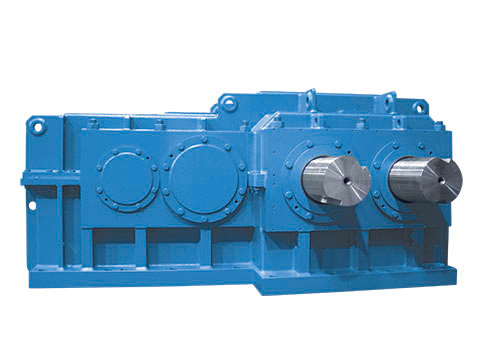

Mixing and kneading processes subject materials to powerful forces. The entire drive train therefore needs to be of a corresponding resilience – especially where large quantities of firm, tough or heterogeneous media need to be processed. DOB gear units prove their mettle under these special conditions, also for briquetting and compacting, as well as in other process engineering tasks.

We provide the rubber and plastic industry with spur gears featuring additional pinion stages. These are mostly used in the mixer systems of the tyre industry. But DOB gear units are also reliably performing their duties in mixers for other technical rubber goods such as sealing profiles, cables and various thermoplastics. The demands placed on them by the environment are particularly great here. Which is why we mostly deliver complete gear units with noise-optimized oil supply systems and noise absorption hoods – all from one source.

We provide mixing and kneading drives for the chemical industry, but also for the food industry, pharmaceutical industry and the processing of ceramic materials. The gear units usually feature two or three output shafts, and are partly equipped with hollow shafts for accommodating heating or cooling pipes.

DOB gear units are also reliably deployed where the briquetting and compacting of materials are concerned – and that in various industries and performance classes. The different processes in the fertilizer, concrete, mineral and metal industries call for individual gear solutions to match. We offer tailor-made solutions.